Gas strut

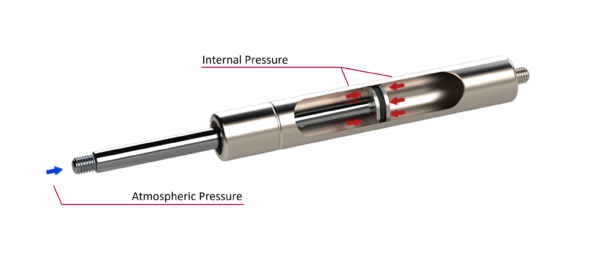

A gas spring, also known as a gas strut, is a type of spring that, unlike a typical mechanical spring that relies on elastic deformation, uses compressed gas contained within an enclosed cylinder sealed by a sliding piston to pneumatically store potential energy and withstand external force applied parallel to the direction of the piston shaft.

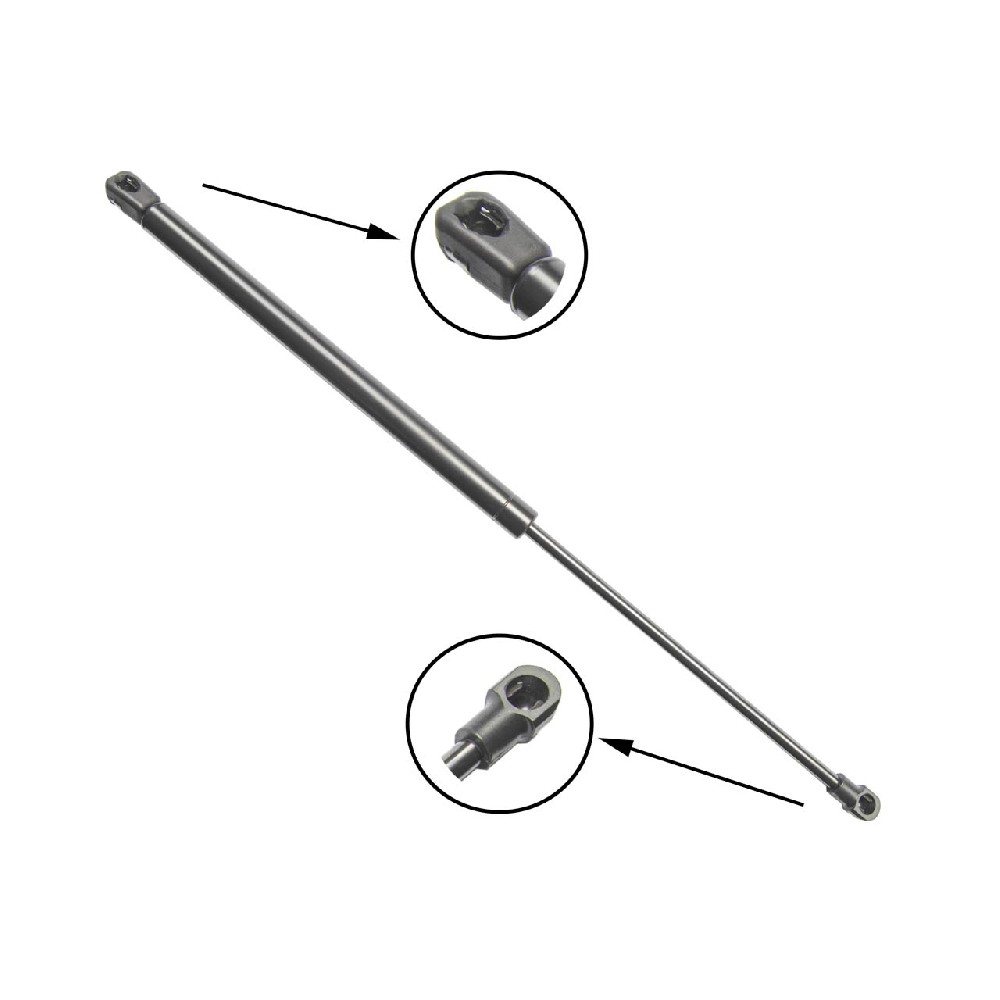

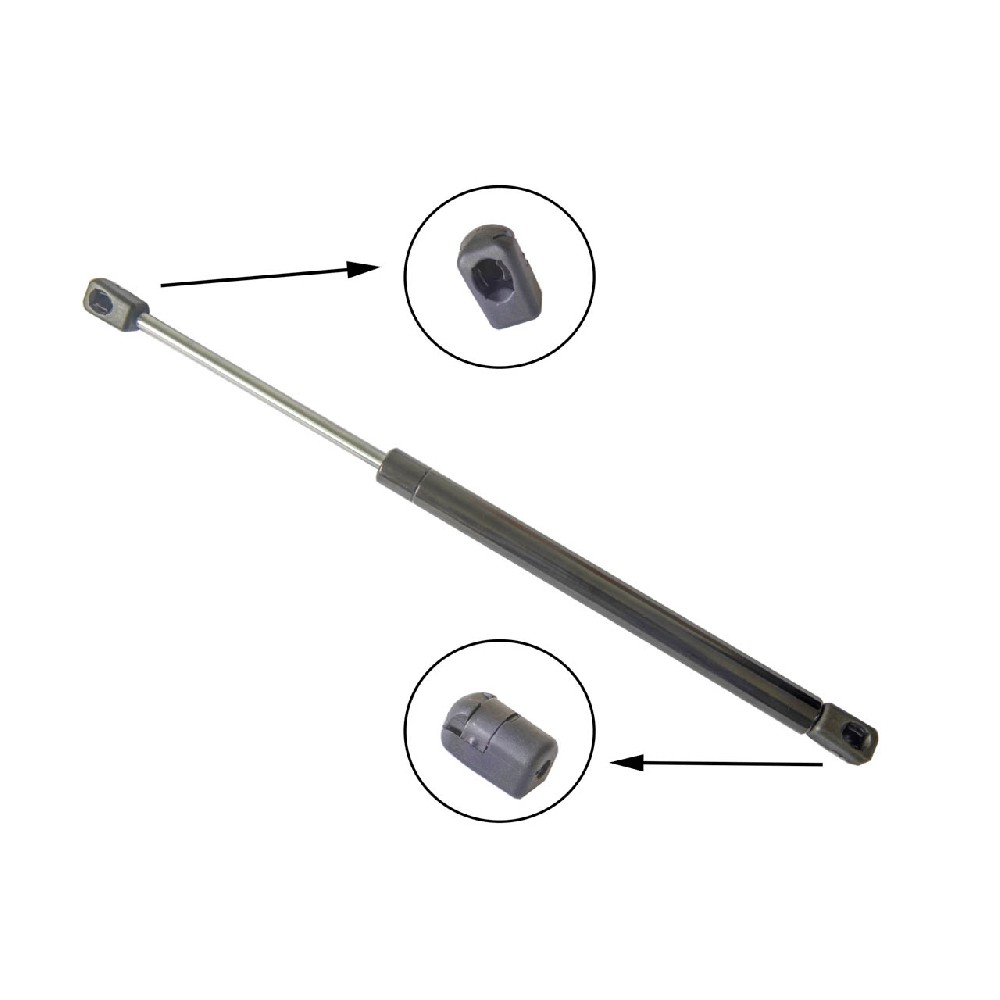

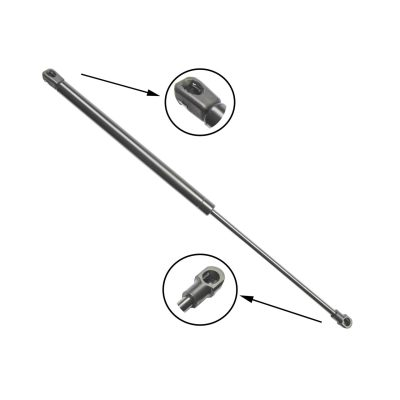

A gas strut comprises of a precision rod attached to a piston and a central tubular body containing compressed nitrogen gas and lubricating oil. When force is applied to the protruding portion of the rod it presses onto the piston head a bit like a plunger on a syringe, compressing the nitrogen gas. This creates an internal pressure that exceeds the pressure outside of the cylinder closing the gas strut. When the force is removed from the external rod the gas is decompressed and the pressure pushes the piston back out again, opening the gas strut.Gas struts or gas springs are available as stop and stay or variable pressure with a steel or stainless-steel body. Depending on application stroke length, extended length, minimum and maximum force ranges and end fittings must be considered.

Gas struts are utilised in a wide range of applications. The most common use is for the gas spring is lifting and lowering of a car boot. Other areas include:

Boat access hatches

Cargo area on aeroplanes

Office furniture and chairs

Skylights

Office chairs and furniture

Machine guards and Conveyor gates